Baseball is a famous sport in many countries. Therefore, baseball equipment is always in demand, making it a potentially lucrative venture for those wondering how to start a baseball glove company.

If you are looking for a dependable manufacturer for your business, you are in the right place.

This blog is the ultimate guide on baseball glove manufacturers. It will help you make the best choice.

Let’s begin!

Table of Contents

- 1. Baseball Gloves

- 2. Baseball Glove Manufacturing Locations

- 3. Top Baseball Glove Manufacturers

- 4. Wholesale Baseball Glove Manufacturers

- 5. Baseball Glove Manufacturing Process

- 6. Types of Baseball Gloves by Baseball Glove Manufacturers

- 7. Parts and Materials of a Baseball Glove:

- 8. Leather used by Baseball Glove Manufacturers

- 9. Sizing and Dimensions of Baseball Gloves

- 10. Finding a Wholesale Baseball Glove Manufacturer

- 11. Customizations offered by Baseball Glove Manufacturers

- 12. Average Price of a Baseball Glove

- 13. Lead Time for Baseball Glove Manufacturing

- Conclusion

1. Baseball Gloves

A baseball glove is an essential part of the game of baseball. Its construction includes leather, padding, webbing, etc.

In a baseball team, players use various types of baseball gloves, and it’s worth noting that the market offers choices from established Japanese baseball glove brands, small baseball glove companies, and a variety of locations where baseball gloves are made to cater to the specific needs and preferences of players. Each type has its purpose, catering to different positions and playing styles in the game.

Baseball glove manufacturers make gloves to suit the needs of players of different body types & sizes.

Pic 1 – A baseball glove

2. Baseball Glove Manufacturing Locations

The key baseball glove manufacturing locations in the world are:

- America

- China

- Japan

2.1 America

Most baseball glove manufacturers are in America. Though, many are outsourcing to other regions to keep costs low. There are only a few manufacturers that make their products locally.

2.2 China

China is known to be a manufacturing hub. It makes all types of sports gloves, including baseball gloves.

Many companies in the west make their products fully or partly in Chinese factories.

Chinese manufacturers like YR Fitness make & supply sports accessories, such as baseball gloves.

According to a study forecast in Global Industry Analysts Inc., the sports glove market in China will grow $178.6 billion by 2026.

Pic 2 – Market research study

2.3 Japan

Japanese companies make quality & versatile baseball gloves. Baseball glove manufacturers in Japan include Mizuno, SSK, & more.

3. Top Baseball Glove Manufacturers

The top manufacturers of baseball gloves include:

Pic 3 – A Japanese baseball glove

3.1 Rawling

Rawling is a baseball equipment company in Missouri, America. It makes baseball gloves, bats, protective gear & much more.

3.2 Nokono

Nokono makes baseball equipment in Texas, USA. It is one of the few companies that makes all of its products locally.

3.3 Marucci Sports

Marucci sports equipment company has its headquarters in Louisiana, USA. It makes a wide range of baseball equipment, including baseball gloves.

3.4 Wilson Sporting Goods

Wilson is a Chinese-owned branch in Chicago, Illinois. It makes baseball gloves & other baseball accessories.

3.5 YR

YR is a China-based company. It is a well-known manufacturer of sports accessories, fitness & strength machines & accessories.

Along with manufacturing, YR is a dependable supplier of its products worldwide.

3.6 Mizuno

Mizuno sports is a Japanese sports equipment company in Osaka, Japan. It is well-known for its quality baseball gloves.

4. Wholesale Baseball Glove Manufacturers

Wholesale baseball glove manufacturers provide quality gloves in bulk. Most of the wholesale manufacturers are in China.

China has the factories, workforce, & training to complete large orders on time. The quality is equal to brand-name products at a much lower price.

Schools, baseball clubs, sports centers, youth leagues need baseball gloves to practice.

It is not cost-effective for them to buy expensive gloves in the long run. Wholesale baseball gloves are the best choice in this case.

You get a good product in bulk that is easy on the budget, as well.

Pic 4 – Wholesale baseball gloves

5. Baseball Glove Manufacturing Process

Baseball gloves from different manufacturers are not the same. Each has pros & cons. The basic manufacturing steps are the same, though.

There are five key steps to making a baseball glove:

- Selecting the leather & cutting different parts of the glove with the help of a die.

- The outer shell is sewn together & the inner lining is put in.

- Protective padding attached.

- The web of the glove is sewn.

- Final stitching & lacing of the baseball glove is done.

6. Types of Baseball Gloves by Baseball Glove Manufacturers

Baseball gloves have different types. Each has its purpose, pros, & cons. A single manufacturer usually makes many kinds of baseball gloves at a time.

The choice of a baseball glove depends on factors, such as the position, size, dominant hand, etc., of the user.

Some of the common baseball glove types are:

6.1 Outfield Baseball Gloves

These gloves have open webbing. These are larger than other gloves. It lets the user have a firm hold on the ball.

6.2 Infield Baseball Gloves

Unlike the outfield gloves, these have a closed webbing. The pockets are not too deep either.

These gloves are for picking & throwing the ball quicker.

6.3 First Base Mitts

The difference between a mitt & a glove is that mitts have no fingers. These are good for catching & releasing the ball quickly.

6.4 Pitcher’s Gloves

These baseball gloves are for pitchers. The web pattern is closed for a secure grip on the ball.

6.5 Catcher’s Mitts

These gloves are bulky & have lots of padding to protect the catcher’s hands. Catcher’s mitts are fingerless, as well.

The gloves also differ on basis of whether a user is right-handed or left-handed.

Pic 5 – Types of baseball gloves

7. Parts and Materials of a Baseball Glove:

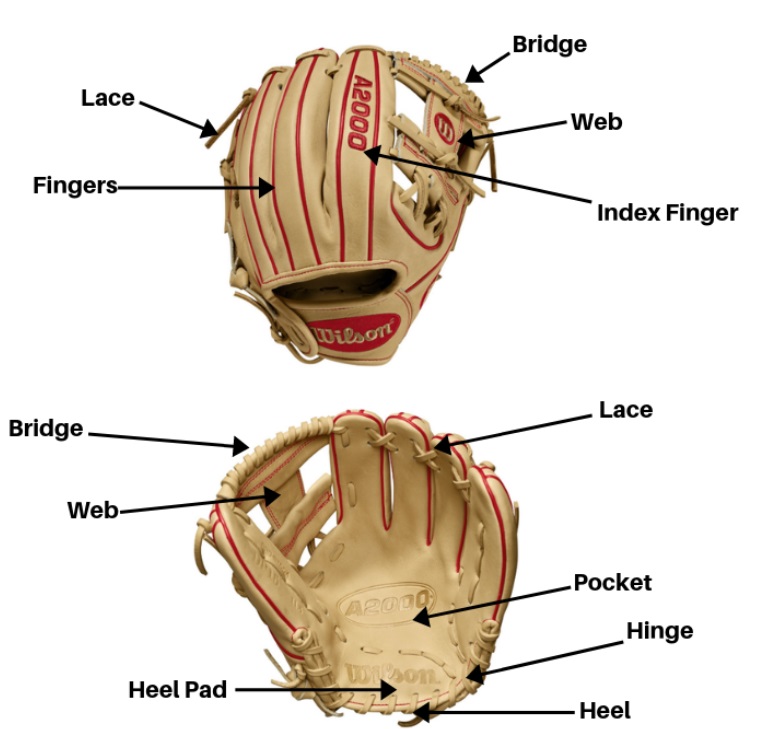

The basic parts of a baseball glove are:

- Bridge

- Web

- Heel pad

- Hinge

- Lacing

Pic 6 – Parts of a baseball glove

7.1 Bridge

It is the topmost part of the glove.

7.2 Web

The webbing is the part of the baseball glove that is between the fingers & the thumb. It is either open or closed.

The webbing has various patterns, such as I-web, H-web, a basket web, Trapeze web, etc.

7.3 Heel Pad

A heel pad is for the protection of the heel of the hand when the ball hits at high speeds.

7.4 Hinge

The function of the hinge is to keep the glove secure on the hand.

7.5 Lacing

The lacing wounds around the glove & keep it compact. It protects the corners of the glove.

Baseball gloves use different types of leather for their construction. There is a small amount of plastic at the base of the fingers as a reinforcement.

Nylon thread is also a part of baseball glove manufacturing.

8. Leather used by Baseball Glove Manufacturers

Leather is the basic material for making baseball gloves. Manufacturers use a variety of different types of leather to increase the durability of their products.

The common types of leather in use for baseball glove manufacturing are:

- Cowhide Leather

- Kip Leather

- Steerhide Leather

- Full Grain Leather

Pic 7 – Leather baseball gloves

8.1 Cowhide Leather

Cowhide leather gloves perform better & are very adaptable. The con is that they lose shape quicker, as well.

8.2 Kip Leather

Kip is a type of soft cowhide. Kip baseball gloves are lightweight & adaptable.

8.3 Steerhide Leather

Steerhide baseball gloves are more long-lasting & durable compared to cowhide gloves. These gloves are heavy & stiff, thus taking longer to adapt to the user’s hand.

8.4 Full Grain Leather

Full Grain gloves perform better & are more durable than other gloves. This type of leather is either cow or steerhide with the natural grain intact.

9. Sizing and Dimensions of Baseball Gloves

The size & dimensions of baseball gloves depend on the age of the player & the position they are playing at.

SIZE OF THE GLOVE | AGE OF THE PLAYER | POSITION IN THE FIELD |

9 inches 11 inches 9 to 10 inches 10 to 12 inches 10.5 to 11.5 inches 12 to 13 inches | Less than 8 years Less than 8 years 8 to 13 years 8 to 13 years 14 years & above 14 years & above | Infield Outfield Infield Outfield Infield Outfield |

10. Finding a Wholesale Baseball Glove Manufacturer

It is an important question to ask. You want quality baseball gloves for your sports club, school, etc., Where will you find one reliable enough to place an order without hesitation?

There are many places one can search for a trustworthy wholesale manufacturer. These include both online & offline options.

Such as:

- Online

- Official websites

- B2B platforms

- Social Media platforms

- Offline

- Sports equipment exhibitions

- Word-of-mouth

10.1 Online

Searching for a wholesale baseball glove manufacturer is not that complex. Use Google. Search for companies overseas.

Look them up on social media platforms, see what their products look like. Read reviews & comments left by other customers.

Visit their official websites. Trusted manufacturers like YR have detailed websites with their products & relevant paperwork on display.

10.2 Offline

Keep an eye out for local exhibitions & tradeshows by sports equipment manufacturers. It will give you a chance to talk to them face to face & check out all the products, as well.

Ask around among your work friends. Maybe they will suggest someone they have worked with before.

Word of mouth is a big source of information.

11. Customizations offered by Baseball Glove Manufacturers

Many baseball glove manufacturers offer to customize the products for their customers. It is especially true for bulk orders.

These options include:

- Logo

- Size

- Color

- Brand name

- Design

Pic 8 – Customized baseball glove

12. Average Price of a Baseball Glove

The average cost of a baseball glove is between $25 to $400. The price depends on many factors, such as brand, material, etc.

High end & expensive baseball gloves are usually for professional games & athletes. Junior players, schools, clubs, etc., prefer the less expensive ones because of rough use.

13. Lead Time for Baseball Glove Manufacturing

The lead time for a custom baseball glove is anywhere from 4 to 7 weeks to as long as 22 weeks.

The lead time includes the time it takes to make the glove & the time it takes the material to adapt to the molding, stitching, etc.

Conclusion

This blog aims to give you all the information about baseball glove manufacturers.

Hopefully, you found it of some help in your search.

Why look elsewhere, though?

With YR you get a trusted manufacturer & a supplier, all in one.

Visit YR Fitness.com & ask for a quote now!

Read more: Top 10 Gym Equipment Brands in China

Related articles: