Choosing the Best Barbell Manufacturer – The Definitive Guide

All gym owners look for reliable barbell manufacturers for their sports centers. They provide essential pieces of the strength training routine. Barbells are popular worldwide amongst weightlifters for their ability to build large muscle masses.

Manufacturers produce several types of a barbell, with many features. You may have questions about barbell manufacturers. So, we prepared the following guide to help in your research.

Let’s start.

Table of Contents

- 1. Importance of Barbell Manufacturer

- 2. Product Description

- 3. Barbell Types Produced by the Manufacturer

- 4. Manufacturers’ Steps to Ensure the Quality of Barbells

- 5. Barbell manufacturer and the International Weightlifting Federation

- 6. Tips to Find a Barbell Manufacturer

- 7. Geographic Segmentation of Barbell Manufacturer

- 8. Key Features of Reliable Barbell Manufacturers

- 9. International Barbell Manufacturer vs Local Barbell Manufacturer

- 10. Communication with Barbell Manufacturer

- 11. Final Words

1. Importance of Barbell Manufacturer

The barbell manufacturer is a key supplier for fitness centers around the world. Barbells are a main strength training tool, appreciated by everyone. The barbell manufacturer fulfills the market demand for barbell workouts.

2. Product Description

2.1 Components of Barbells

Manufacturers produce barbells with 4 main parts:

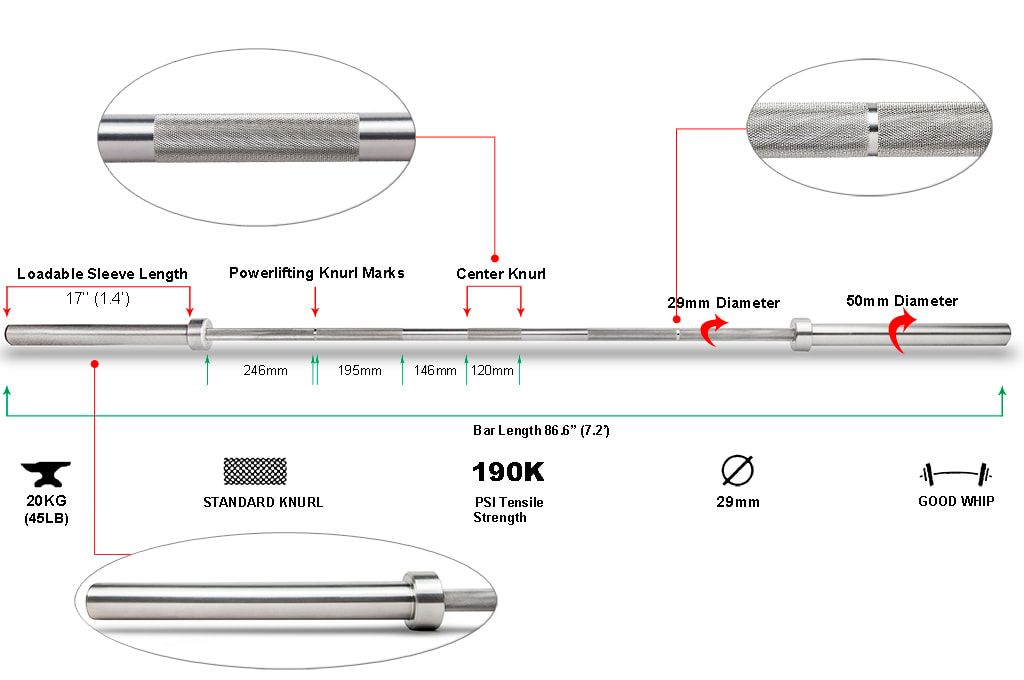

Shaft

The shaft represents most of the length of the bar and it’s the middle part of it. This is produced from a special steel and only a few manufacturers make it. Most shafts are imported from China and Canada.

Sleeve

The sleeves are located at the end of the shaft, on both sides. Its purpose is to secure the area where the plates are loaded.

Collars

The collars are integrated into the sleeves. It is thick enough to prevent the plates from sliding onto the shaft.

Knurling

This part of the barbell is located on the shaft. It is a pattern with different sizes and shapes and is crucial to have a good hold of the bar while training. Some barbell models do not use knurling.

Figure number 1. Components of barbells

2.2 Manufacturing Materials

For long-lasting barbells, manufacturers use 2 main types of materials:

Steel

Stainless steel is the most frequent material for commercial-grade barbells. But of course, there are many steel mixtures and grades. According to studies, the best steel manufacturers use for barbells is molybdenum-alloyed steels, with a yield strength of 655/852 MPa.

Alloying elements such as tungsten, vanadium, silicon, nickel, molybdenum, and manganese are famous for increasing the strength of carbon steel. Nickel is especially known for increasing hardness and toughness. For corrosion resistance, HSLA steels are the best option.

Steels with yield strength levels over 780 MPa are called “ultrahigh-strength steels”. for tensile strengths exceeding 1000 MPa is often called “GigaPascal steel” (1000 MPa = 1GPa).

Reliable manufacturers offer plenty of information about the steel type and its alloy mixture. In this way, you can choose the best barbell, according to your gym-specific training.

Iron

Iron is a more accessible material for barbell manufacturing, easier to obtain, and less pretentious. But this material is mostly used for low-quality barbells. It’s best to avoid this.

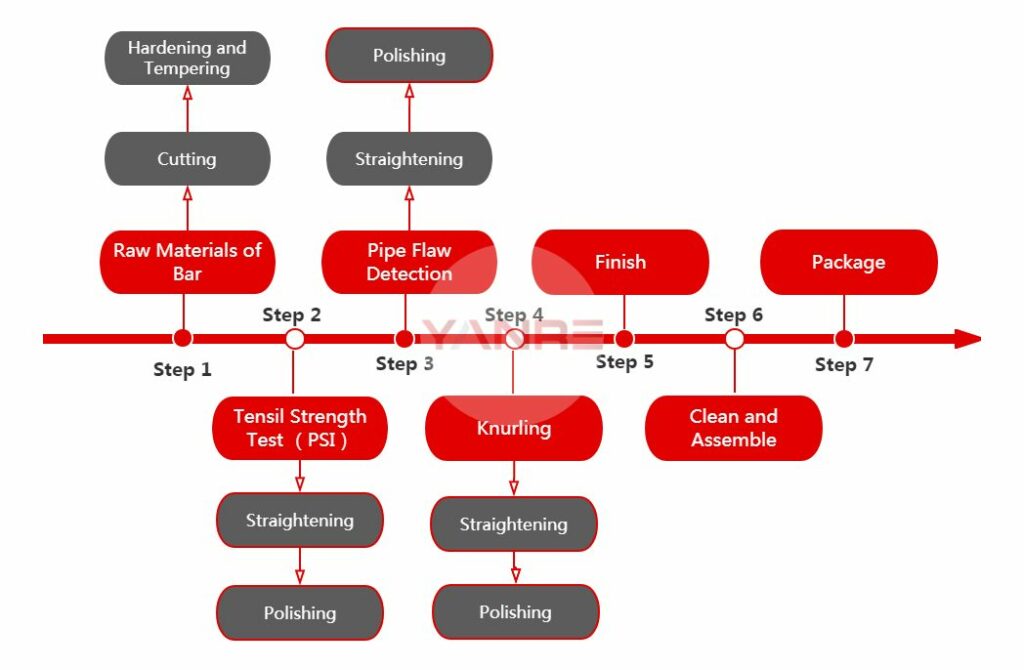

2.3 Manufacturing Process

The first step in manufacturing barbells is starting with the ground and polished steel. After this, the raw material is put into a special machine and cut the snap ring grooves.

The manufacturing process is decisive for the quality of the future barbells. For example, cold worked austenitic stainless steel is one method that eliminates heat treating and secondary operations. This means that this procedure can minimize many mechanical failures such as straightening, secondary machining, and so on.

To make the manufacturing process clearer, have a look at the following How it’s made video:

2.4 Accessories and Extras

Spinning Sleeves

This helps reduce the amount of force produced by the weight plates during the inertia. Rotating sleeves provide smooth lifting experiences and keep the health of the wrists and elbow.

Bearings

This is a supplement that allows the sleeve to rotate independently of the shaft. The bearings are crucial in maintaining the functionality of barbells, especially if they fall repeatedly on the floor.

Fastener

The fastener has the role to attach tightly the sleeve to the bar.

End Caps

A plastic or metal cover is used to close the sleeves.

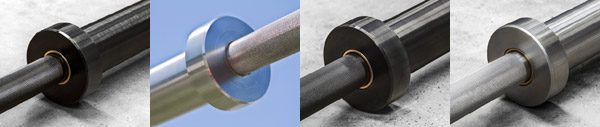

Shaft and Sleeves Finish

The finish of the barbell means the treatment of the shaft and the sleeves, which will give rise to different looks. The most common finish types are:

- Bare Steel

- Black Oxidation

- Black Zinc

- Hard Chrome

- Decorative Chrome

- Bright Zinc

- Cerakote

YR Fitness provides superior finish treatment to its barbells so that all the bars meet the competition standards. With YR, you make sure of the best barbells for your commercial gyms.

Figure number 2. Barbell and sleeve finish

2.5 Size and Weight

Most barbells are between 1200 mm to 2400 mm long of a straight bar and have 25 mm to 32 mm of thickness.

The standard barbell size worldwide for general training purposes is 2200 mm. Generally speaking, the size of the bar should ensure sufficient length to take all hand positions.

Standard empty barbells weigh about 20 kg.

Figure number 3. Size of barbells

YR Fitness is a top commercial quality barbell supplier that provides high-end bars, suitable to the vast majority of gyms and fitness centers.

3. Barbell Types Produced by the Manufacturer

There are many types of barbells available on the market. It all comes down to form, user and function. For an easier understanding, have a look at the 3 main categories:

3.1 Barbells by Form

- Straight bars

- Curl bars

- Trap bars

- Swiss bars

3.2 Barbells by User

- Men

- Women

- Juniors

3.3 Barbells by Function

- Powerlifting bars

- Olympic bars

- Deadlifting bar

- Squat bar

- Multi-purpose bar

A major bar manufacturer may offer over 40 types of barbell available for sale. Most manufacturers are open to any negotiations regarding extras and customization of the barbell.

4. Manufacturers’ Steps to Ensure the Quality of Barbells

In order to produce superior barbells, manufacturers must ensure some key features:

4.1 Load Capacity

The standard commercial bar can withstand a load of up to 100 kg (about 200 lbs). Olympic barbells can take up to 500 kg (1200 lb). Any weight beyond this point may damage your barbell.

4.2 Premium Raw Materials

The resistance to intense training as well as its lifespan is determined by the quality of the barbell. Premium manufacturers only use quality raw materials, such as certified steel.

4.3 Whip

Whip, or the ability to bend under tension, is a key feature of barbells. The whip is important to athletes that are training heavy. The amount of whip is given by the material of the bar.

4.4 Fatigue-Proof Steel Bar

This feature is obtained by treating the steel without heating. This ensures the elimination of secondary machinery operations, thus, superior steel bars.

4.5 Tensile Strength

The breaking point of a barbell is rated in pounds per square inch (PSI). High-end manufacturers produce their fitness barbells with at least a 180.000 PSI rating.

4.6 Rust-resistant

Barbells are inclined to rust and oxidize in time. To prevent this, barbell manufacturers treat the surface with coating substances or sprays.

Be aware that bare steel is inclined to oxidize faster, while paints such as chrome or cerakote have more resistance.

If you want to confirm any of these features, please contact YR Fitness today.

Figure number 6. Rusted barbell

5. Barbell manufacturer and the International Weightlifting Federation

Manufacturers produce barbells for regular gym use and competition use. Competition use barbells are more strict and respect even more quality standards. In order to produce it, reliable barbell factories must comply with all International Weightlifting Federation specifications.

The institution must afterwards give its approval and award a certificate. Markings and dimensions are crucial specifications for competition use of barbells.

6. Tips to Find a Barbell Manufacturer

According to specialty sources, there are many high-quality manufacturers on the market. In your search for a reliable barbell manufacturer, you can use the following methods:

6.1 Internet

Nowadays, there is no greater library than the internet, where you can easily find worldwide barbell manufacturers. You just google the term and thousands of results will appear instantly.

However, remember that not everything you find on the web is reliable.

6.2 Profile Exhibitions

A more practical way to find barbell manufacturers is to visit gym and sports exhibitions and trades. To such events, only companies with experience and good quality products are accepted.

They usually bring samples from their barbells and you have the chance to see, touch and even try. You may find a reliable manufacturer here and can negotiate some of the business terms.

6.3 Factory Visits

One popular approach today is getting a factory visit invitation. This means that you can go directly to the manufacturer’s headquarter and see how he is actually producing the barbells, the materials, and the standards.

6.4 Gym Owners’ Feedback

If you have among your friends gym owners, ask for their opinions. Where they supply from and how is the business relationship with the barbell manufacturer.

For more information about barbells and manufacturers, please access the link:

http://library.crossfit.com/free/pdf/60_07_Where_Barbells.pdf

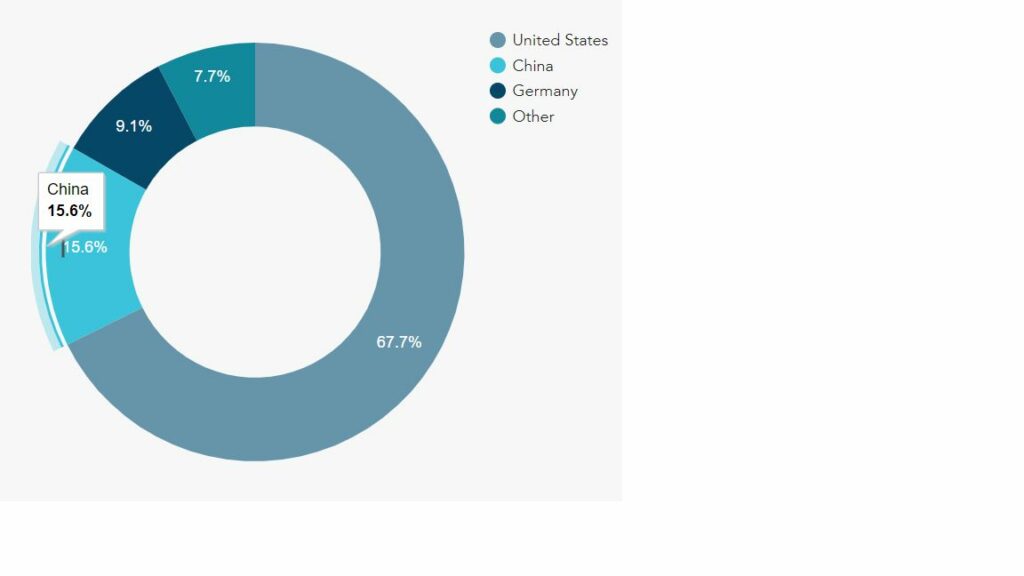

7. Geographic Segmentation of Barbell Manufacturer

According to the Fitness Equipment Manufacturing Research, the fitness industry is mainly located in key areas:

- United States of America

- China

- Germany

The competitive landscape is driven by demand. Consumer income is greater in the US. In China alone there are over 1.000.000 people using barbells for their daily workout. Larger brands have reputation, smaller brands have unique products.

YR Fitness is in the top three Chinese premium barbell manufacturers. Our products represent the quality standards at national scale and export to many American and European gyms and fitness center owners.

Figure number 7. The geographical representation of main barbell manufacturers

8. Key Features of Reliable Barbell Manufacturers

8.1 Reputation

One important feature of reliable barbell manufacturers is their reputation on the market. If their products are superior and reach many clients, this manufacturer will have a strong position.

Reputation is built over time, so look at the history of the company and its manufacturing figures.

8.2 Quality

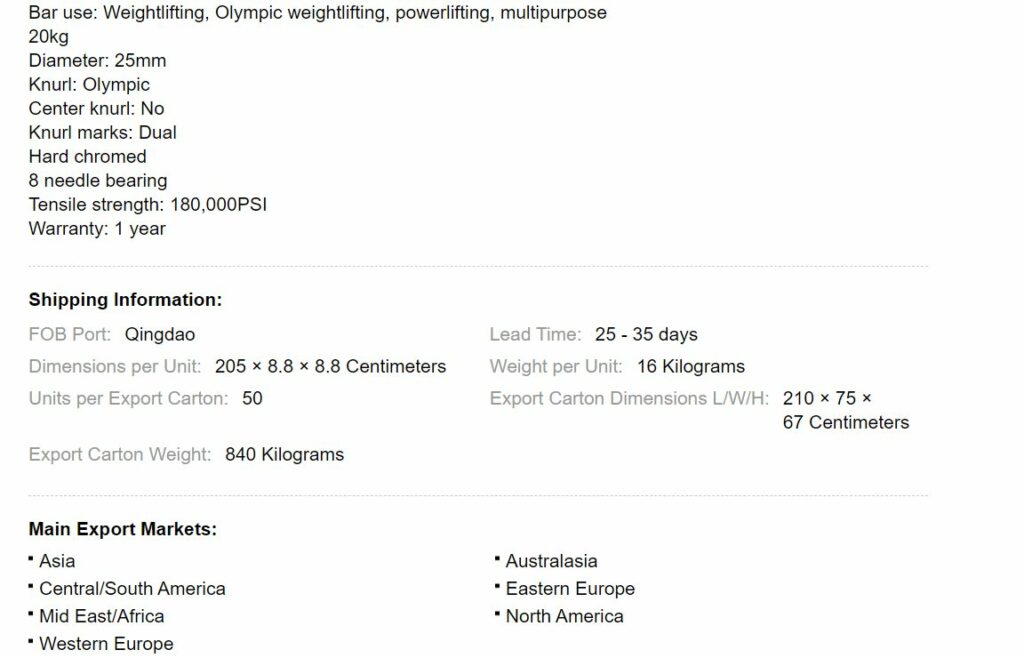

When it comes to quality, a great barbell manufacturer will provide insights into specific information. Specification such as how long the bar will likely last, tensile strength, material, and so forth are always visible and public. Reliable barbell manufacturers will praise its top features.

8.3 International networks

Big barbell manufacturers normally produce other types of gym equipment too. Because they offer a wide range of equipment, it’s more likely to have international connections. This means that this manufacturer fulfills the quality demands of worldwide clients.

International networks offer the advantage of transparency in business and are easier to track and communicate with. Just look at their main export markets and you will see if the manufacturer can be trusted or not.

Figure number 8. Gym barbell export market example

8.4 OEM and ODM skills

For big barbell manufacturers, ODM and OEM skills are crucial when it comes to customization of the barbell. Reliable ones even have their own self-design unit, which helps in offering a general view of the barbell before production.

8.5 Price

Price is an advantage of the barbell manufacturers because they do not use an intermediate. So their price is smaller than that of the gym equipment shops.

8.6 Mass Production

For all gym owners, the best option for bulk orders is the barbell manufacturer. He is the only one who can deliver mass production barbells. Manufacturers have the machinery, the knowledge, and the experience of mass production barbells.

8.7 Fast Delivery

Normally, a reliable barbell manufacturer has standard procedures. For him, making a sample of your product should not take more than 7 days.

This is why all orders, even bulk ones, are delivered fast and organized. Customers get their required barbells and other gym equipment in time.

8.8 International Safety and Quality Standards

All reliable barbell manufacturers respect international safety and quality standards. Certifications such as ISO or SGS are some of the international companies that check the quality of the manufactured barbells.

Inspections are conducted to the factory of the manufacturer and include some important benefits. We listed the most relevant in the table below:

| Product failure procedure. This will reduce costs due to the disposal of faulty goods instructions and make sure the manufacturer respects the delivery time. |

| Avoid recalls and reputational damage. This will reduce the complaints and strengthen the manufacturer’s image on the market. |

| Anticipate production and reduced lost days |

| Improved communication between the manufacturer and the client |

| Quickly fix any product issues identified by the client/quality check |

| Ensure quality at every production stage |

Figure number 9. Controlled barbell manufacturing steps

9. International Barbell Manufacturer vs Local Barbell Manufacturer

If it were to choose between an international and local barbell manufacturer, take a look at the pros and cons in the comparison chart below:

International barbell manufacturer | Local barbell manufacturer |

Worldwide connections | Small business for local clients |

Wide range of barbell models and qualities | Limited amount of barbells |

Affordable price | Higher prices |

Mass production | Small capacity of production |

Situated in another country / continent | Closer to the residence |

International quality certification | Local certification |

10. Communication with Barbell Manufacturer

Manufacturers are normally easy reaching and have clear information about this subject. You can contact them via email, phone or write a request. For international suppliers it is important to speak at least one international language, such as English.

If your barbell manufacturer is having trouble communicating with you, or does not speak English, it’s best to avoid. You may have misleading information or misplaced products. You can even get other items outside your order.

11. Final Words

I hope the above guide has answered most of your questions about barbell manufacturers.

If something is still questionable, contact YR Fitness to clarify all doubts.

Are you looking for barbell manufacturers? YR Fitness is your premium barbell supplier to equip the gym. Contact YR Fitness and get a quick quote today.